WASTEWATER TREATMENT PLANT | ECODEPUR® SBR

View models and dimension table (click here)

| MODEL | Volume (l) | Dimensions (DxLxH) |

|---|---|---|

| SBR VT10 | 10.000 | 2.190 x 3.440 x 2.265 |

| SBR VT15 | 15.000 | 2.190 x 4.980 x 2.265 |

| SBR VT20 | 20.000 | 2.190 x 6.520 x 2.265 |

| SBR VT25 | 25.000 | 2.190 x 8.060 x 2.265 |

| SBR VT30 | 30.000 | 2.190 x 9.600 x 2.265 |

| SBR VT35 | 35.000 | 2.190 x 11.140 x 2.265 |

| SBR VT40 | 40.000 | 2.190 x 12.680 x 2.265 |

| SBR VT45 | 45.000 | 2.190 x 14.220 x 2.265 |

| SBR VT50 | 50.000 | 2.980 x 8.520 x 3.050 |

| SBR VT60 | 60.000 | 2.980 x 10.060 x 3.050 |

| SBR VT70 | 70.000 | 2.980 x 11.600 x 3.050 |

| SBR VT80 | 80.000 | 2.980 x 13.140 x 3.050 |

| SBR VT90 | 90.000 | 2.980 x 14.680 x 3.050 |

| SBR VT100 | 100.000 | 2.980 x x16.220 x 3.050 |

| SBR VT110 | 110.000 | 2.980 x 17.760 x 3.050 |

| SBR VT120 | 120.000 | 2.980 x 19.300 x 3.050 |

Legend:

L - Length | H - Height | I - Width | LT - Overall width | D - Diameter | C - Cover | He - Cota Piping Input |

Hs - Piping Output Quota | FT - Technical Data | DT - Technical Drawing | The dimensions (in mm) are given as an indication, with tolerance of ±2%, and can be changed without notice.

Hs - Piping Output Quota | FT - Technical Data | DT - Technical Drawing | The dimensions (in mm) are given as an indication, with tolerance of ±2%, and can be changed without notice.

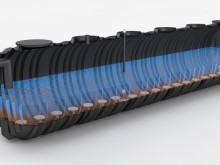

ECODEPUR®SBR are a Compact System specialized in domestic wastewater treatment in one Biological reactor by Sequence Batch Reactor (SBR) in na Activated Sludge process.

FEATURES

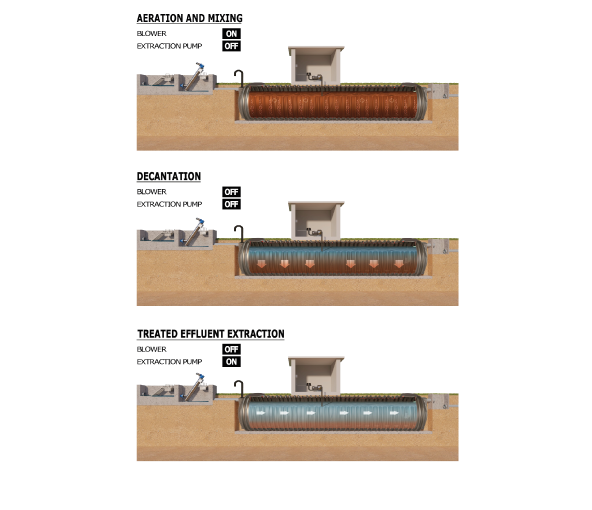

- Automatical Sequencial function – BATCH System;

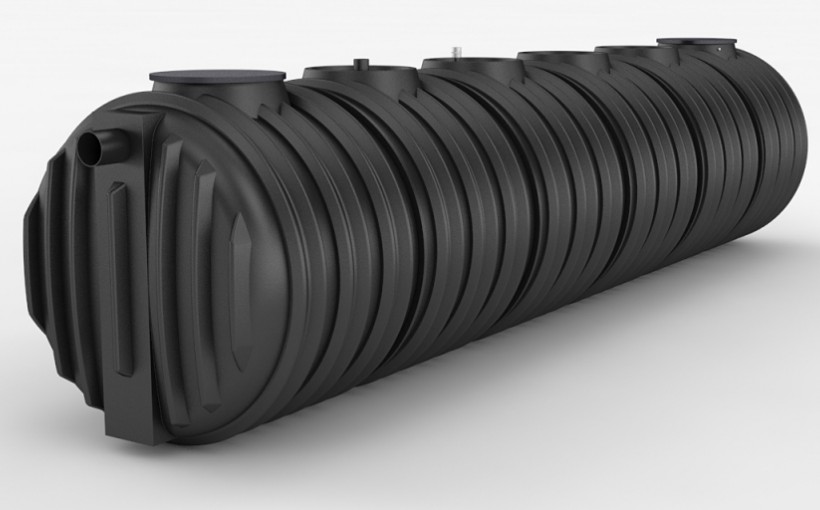

- Constructed in Polyethylene tank or Steel Tank;

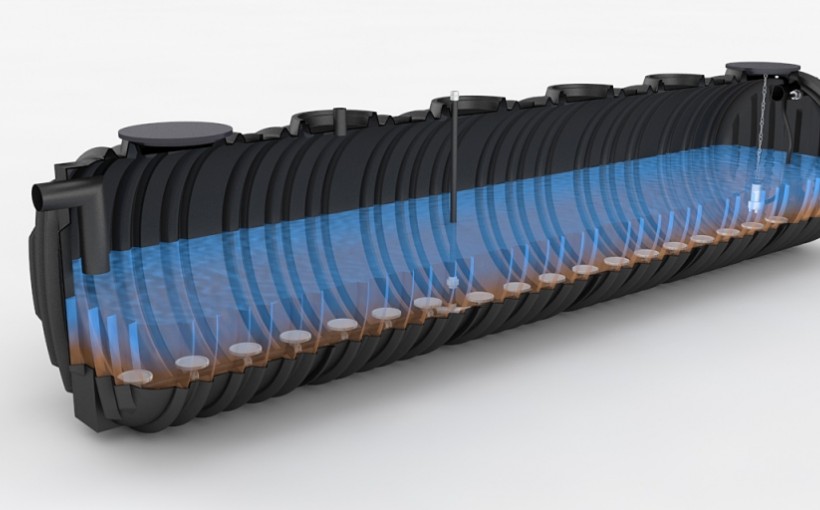

- Activated Sludge process, in low-loaded/total aeration system (total oxidation);

- High treatment levels;

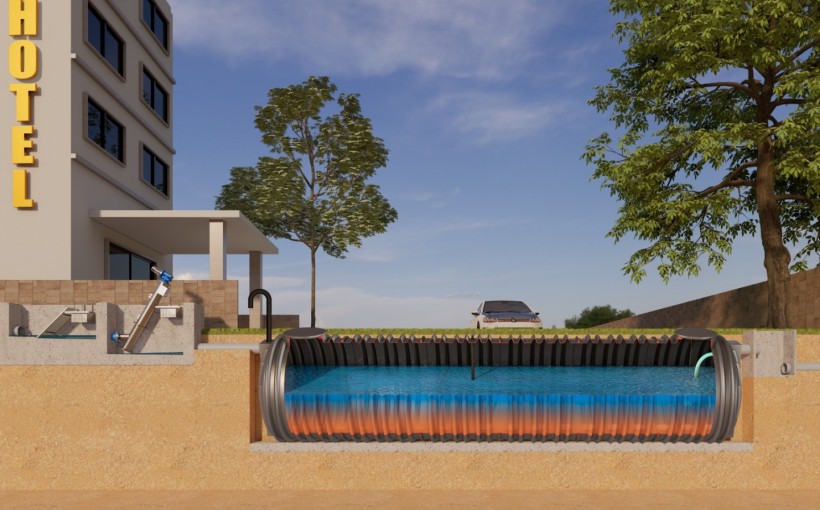

- Null visual impact (Underground Installation);

- Easiness and speed of installation;

- Manufactured in additive linear polyethylene anti-UV, by rotomoulding system, which confer elevated mechanical resistance and insensitivity to corrosion;

- Absence of unpleasant odours;

- Functioning and maintenance simplicity;

- Aeration and agitation secured by only component in high profit conditions;

- Automatic functioning (electric board with integrated delayer);

APLICATION

- Small population clusters;

- Condominiums;

- Tourist complexes;

- Service Stations;

- Restourants ;

- Construction sites;

- Schools;

- Athletic complexes;

- Camping;

- Military facilities;

- Petroleum and gas exploration field;

- Component maid of wastewater produced in industrial unities, between others.

OPERATION

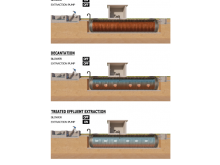

Ecodepur SBR operates in a true batch mode with aeration and sludge settlement both occurring in the same reactor.

MAINTENANCE

The treatment unity simplicity, allied to its automatic functioning allows restricting its maintenance to a set of routine operations which frequency will be dictated by the normal exploration practice.

Documents